Gas Detect Cart

TAS’ advanced gas detection cart system focuses on monitoring H2S and LEL gases. Utilizing MSA’s cutting-edge Ultima x5000 Gas Monitor, the system features a portable cart design with solar power and battery backup for 24/7 operation. With a 360° audible and visual warning system, aluminum construction for durability, and certification for hazardous environments, TAS, as a certified premier system integrator, provides a comprehensive automation solution, including PLC, SCADA, communications, and panel services, delivered by local in-field automation specialists.

Solar Power Skid

TAS’ Solar Power Skid is designed for off-grid power in industrial applications, delivering a continuous 100 watts at 24VDC. With a minimum autonomy of 3 days without sunlight, it offers easy transport and setup. Customizable based on specific requirements and location, the skid features Grade “A” solar panel technology with three 370-watt panels, Absorbent Glass Matt (AGM) batteries (six at 250AH each), a state-of-the-art charge controller, and a durable painted steel skid (galvanized steel option available) ensuring reliable and efficient performance for various energy needs.

Heat Trace Control

TAS’s Heat Trace Control is meticulously built and tested in their UL508a/NNNY certified panel shop, ensuring high standards of quality. The offering includes professional drawing packages and is customizable to meet specific requirements. The heat trace control units are designed as stand-alone with visual status indicators, and optional features include remote control and monitoring capabilities. The system provides flexibility in power supply options and offers Class 1 Division 2 design choices, catering to diverse needs for efficient and tailored heat trace control solutions.

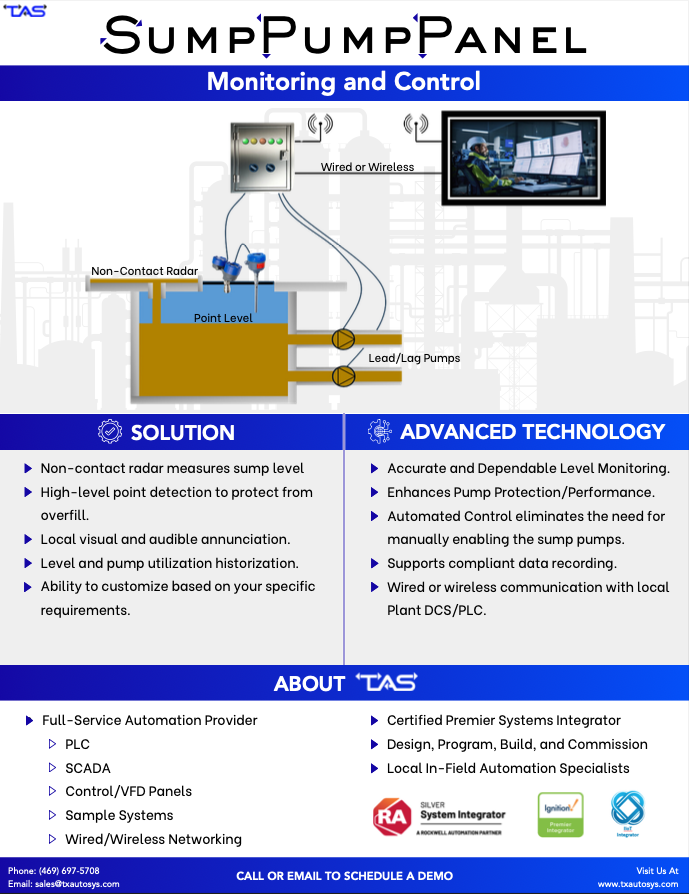

Sump Pump Panel

TAS’s Sump Pump Panel for monitoring and control employs non-contact radar for precise sump level measurement and high-level point detection to prevent overfill. It features local visual and audible alerts, along with historization of level and pump utilization. The system is customizable to meet specific requirements, offering accurate and dependable level monitoring, enhancing pump protection and performance. With automated control eliminating the need for manual activation of sump pumps, it supports compliant data recording and allows wired or wireless communication with local Plant DCS/PLC for seamless integration.

HMI Defender

TAS’s HMI Defender is purpose-built to enhance visibility of Human Machine Interface (HMI) in bright and glaring conditions. It not only protects the HMI from accidental damage during inactive periods but also adds an additional layer of physical security with a locking mechanism for controlled access. The inclusion of a gasket ensures the integrity of the enclosure seal, providing a comprehensive solution for safeguarding and optimizing the performance of HMIs in various environmental conditions.